Monitor production in real time with SCHEDULER.DE.

Two visualization options are available, which complement each other perfectly.

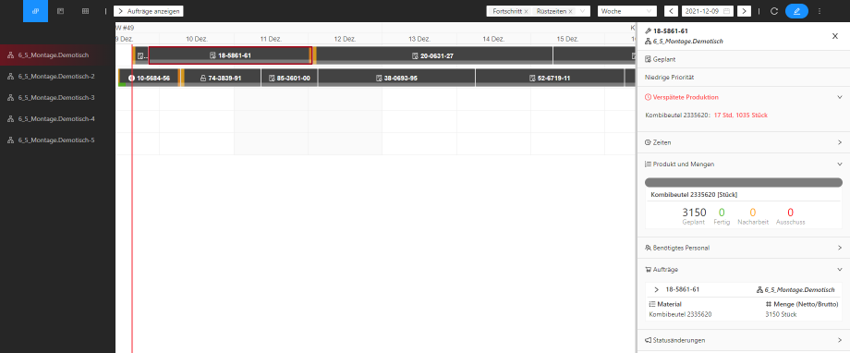

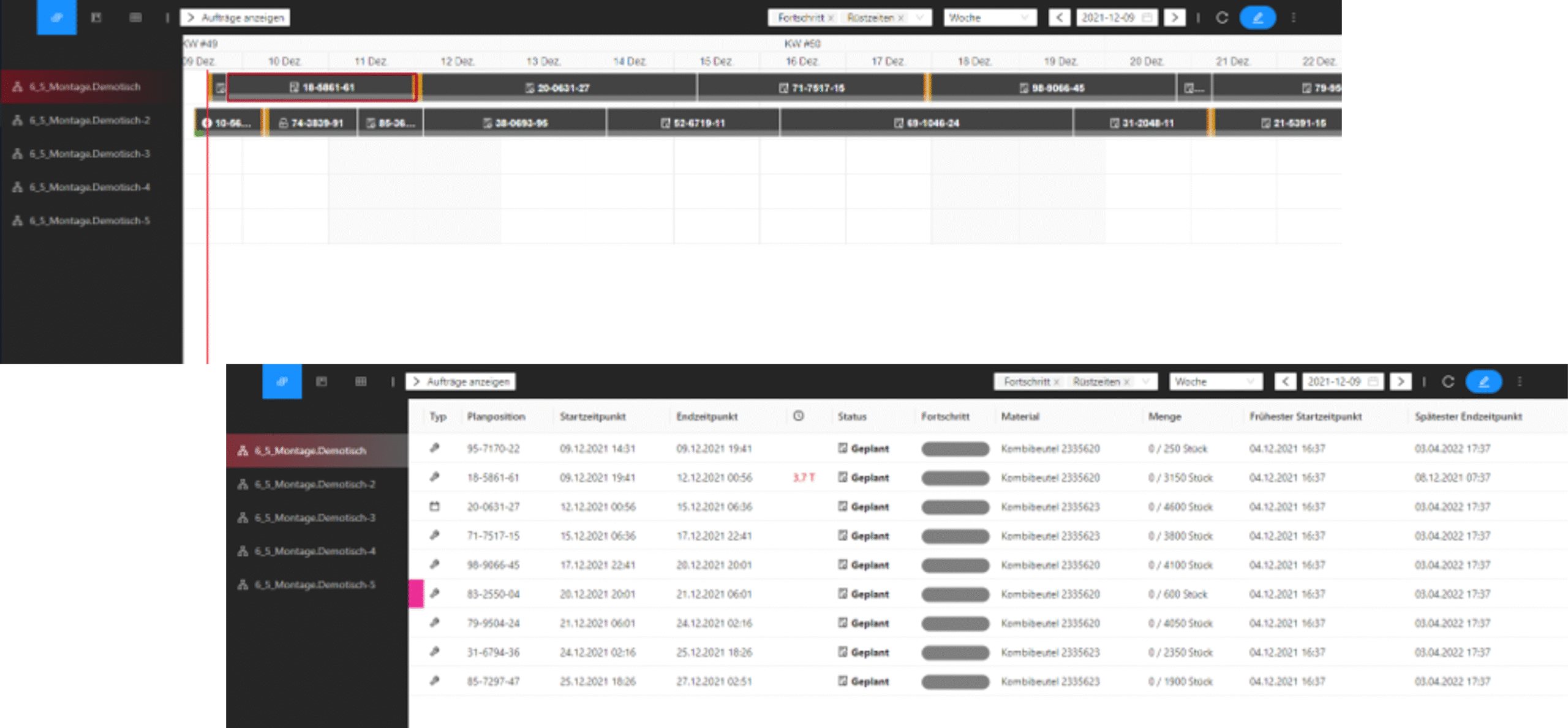

For a quick overview, use our clear planning board in the form of a Gantt chart. Here, you can view all ongoing and upcoming production orders in parallel and immediately see which orders are on schedule or whether discrepancies such as delayed productions or unplanned downtimes have occurred.

For a detailed view of each production line or machine, the table view is recommended. In this view, all orders scheduled for production are displayed in a table with all necessary details.

In both views, selecting an order opens the order detail view, which summarizes all relevant information as well as all quantities and timestamps recorded so far.

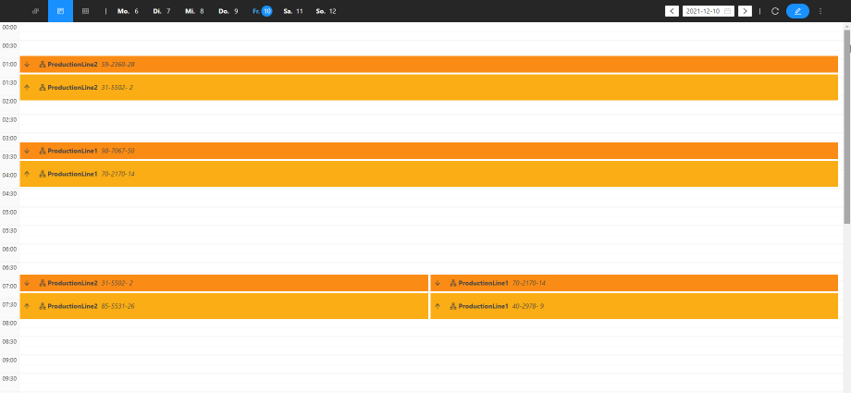

For setup planning, it is essential to be able to view all upcoming setup and disassembly operations along with the affected production line or machine at a glance. This allows for optimal personnel planning of the setup team and enables bottlenecks to be resolved before they arise.

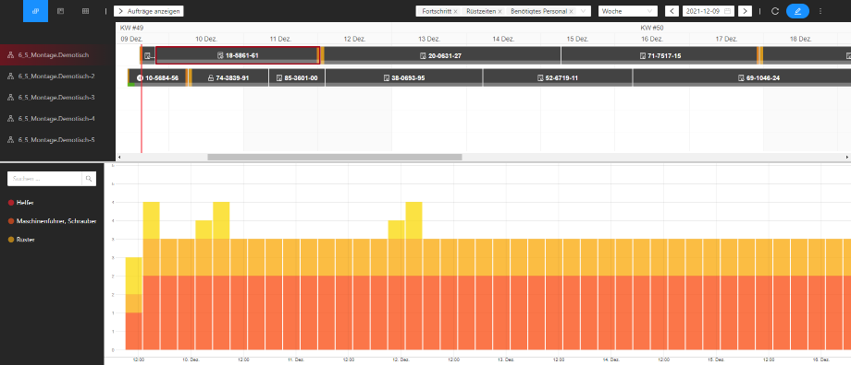

An overview of which personnel is needed during which period is one of the core topics of modern production planning.

In SCHEDULER.DE, the anticipated personnel requirements are summed up across all production lines and presented graphically.

This graph is linked to the Gantt view so that it is always clear when which personnel is needed and which orders are scheduled at that time.

The personnel graph can be filtered by qualification groups if certain groups need to be given special attention in the current planning.

The highest priority of a production planner is to schedule upcoming orders on time as to meet subsequent process steps or customer deadlines. To provide the optimal basis for decision-making, every scheduled order is monitored in real time and continuously updated based on production feedback.

As soon as there is an order on a production line that is not scheduled on time, the planner is informed in three stages: by coloring the affected production line, by marking the affected order with a distinctive red border, and by providing a direct statement about the exact delay and the quantity produced late.