Project Description

Production planning in real time

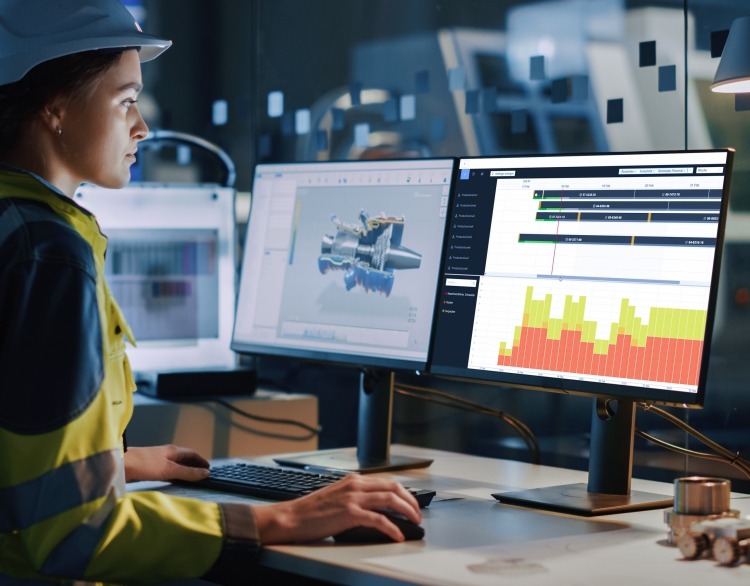

SCHEDULER.DE is a detailed planning tool, which will allow you to see the progress of your production in real time in an attractive and user-friendly view to enable you to make the right planning decisions at any point of time.

Thanks to our real-time integrations providing insight into production, including status and quantity feedback- loops, you can react to potential delays before they occur.

This will allow you to avoid expensive wait times!

- As-is state of production in real time

- Production plan as Gantt and table formats

- Set-up plan as a calendar

- Expected resourcing requirements

- Expected material requirements

- Expected energy demand

- Delay with expected shortage

- Calculate set-up times according to set-up matrix

- Automatic / manual scheduling

- Planning in simulation mode

- etc.

SCHEDULER.DE works across multiple working stations and production lines and works bi- directionally. There is a constant exchange of data between the shop floor and planning station.

Is state of production in REAL TIME

Once your production process is connected to the SCHEDULER via an interface, any changes will be immediately visualized in SCHEDULER.DE. You always have an up-to-date view of the production showing any potential issues, this will help you to intervene quickly if necessary.

Production plan as GANTT & table

There are two visualization options that complement each other perfectly.

For a quick overview, you can use our clear planning board as a Gantt chart.

Here you can view all current and pending production orders in parallel and see at a glance which orders are on time and whether there are any discrepancies such as delayed production or unplanned downtimes.

The table option can be used as a detailed view for each production line or machine. This view will display all the scheduled orders relevant for the selected production line including all their essential details.

Set-up plan as a calendar

When planning the set-up of a production line, it is crucial to see all the upcoming set-up events including the demobilization of processes for the affected production line / machine at a glance. This will allow an optimal usage of the set-up team as well as the elimination of bottlenecks before they arise.

Expected staffing requirements

The overview of which personnel is required in a specific period of time is one of the core strengths of a modern production planning system.

In SCHEDULER.DE, the required personnel demand across all applicable production lines is summarized and presented in a user-friendly graphical view.

The different views are highly integrated and will allow the user to see any personnel demand and availability in a Gantt view at any point of time. In addition, to increase the attention to specific personnel groups and to improve user experience, filters can be applied.

Delay with expected shortage

The highest priority of a production planning tool is to schedule the upcoming production orders on time to ensure conformity with the sequential processes as well as customer timelines. In order to provide the best possible baseline for decision-making, each pending production order is monitored in real time and updated continuously based on the integrated production feedback-loops.

As soon as there is an unscheduled delay identified by the system, the planner will be informed in three possible ways:

1) Coloring of the affected production line

2) Coloring of the affected job/production order with a distinctive red frame

3) A specific statement about the exact delay and the associated shortage

Manual / automatic scheduling

SCHEDULER.DE offers various levels of automation in order to be integrated into your planning process in the best possible way. You can switch between the levels when and as required.

Level 1 – Manual planning

New incoming orders appear in an order list and are manually scheduled by the planner at the desired position.

Level 2 – Auto Attach

New incoming orders are attached at the end of the master schedule of the specific production line.

Level 3 – Plan for the optimized

New incoming orders are scheduled at the optimal point in the production plan (alternative lines are also considered). The rest of the production plan stays unchanged. The prioritization of all other orders in the production plan is retained.

Level 4 – Proposal of continuous optimization

The production plan is continuously optimized and new incoming orders are directly included. The newly calculated optimal production plan is presented to the planner as a proposal.

Level 5 – Autonomous Planning

The production plan is continuously and autonomously optimized and new incoming orders are directly included. The newly calculated optimal production plan is adopted automatically..

Planning in simulation mode

Not every consideration for a production plan should be adopted directly to production. In SCHEDULER.DE, manual production planning always takes place in a simulation mode that analyses and evaluates the simulated production plan taking the active production plan into consideration.

This allows the production planner to test new sequences first, checking the boundary conditions, personnel availability as well as delivery reliability before either discarding the plan or proceeding with the dispatch to production.